hammer mills

- universal use

- power 44kW – 100kW

- high troughtput capacity due to optimum ratio between blows and screen surface and maximum utilisation of the

- grinding chamber

- fine, rough and preliminary crushing through the use of various hammer crushers and screens

- versatile possibilities of use

- tough construction

- high performance

- long lifetime & low replacement costs

technical data

- grinding width 500mm or 600mm

- revolution speed of rotor: 1000 min-1 to 1200 min-1

- weight: approximately 2500kg without drive

- throughput of food residues approximately 16t/h depending upon consistency at a grain size of approximately 10mm

range of use

e.g. milling of food residues for feeding into the biogas plant

product information

- welding construction – shatter proof and long lasting

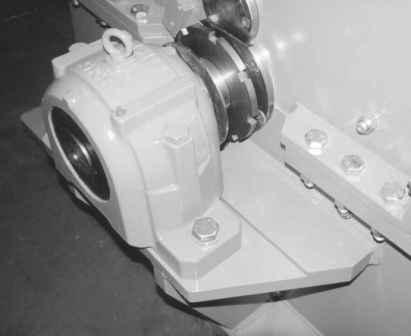

- storage of the mill spindle in plummer blocks outside of the product room

- hammer crushers – with double -sided use, made of wear resistant steel alloy

- screen with round holes or special holes – depending upon requirement of use

- polydirectional, replaceable wear plates within the whole upper and lower part of the mill

- suspension eyes for easier handling during installation

- foreign material separation box

- opening for cleaning and inspection

- various openings for CIP (Cleaning in Place) and liquid inlet – upon customer requirement

inside view

bearing